Diamond Electric Develops Long Life, A6-sized 1 kW Isolated Bidirectional Charger

January 17, 2020

Diamond Electric to start mass production of Multi-spark Ignition Coil

January 17, 2020Prolonging Power Converters’ Life Seen Contributing to Spread of EV and Energy-Saving Equipment

OSAKA (Japan) ― Diamond Electric Mfg. Co., Ltd. developed an “electrolytic capacitors-less” power converter technology in May 2019. The technology reduces the capacitance needed in inverter by 93% and can substantially downsize, extend the operation temperature, and prolong the life of the inverter, and is expected to contribute to spreading electric vehicles (EVs) and energy-saving equipment such as solar inverters.

In recent years, demands for energy-saving equipment are increasing as a countermeasure for global warming. In response, Diamond Electric has set the energy-saving technologies as one of its key technologies in the 5 years business plan, DSA 2021. In most of energy-saving equipment, inverters and/or power factor correction (PFC) circuits are implemented. These circuits use electrolytic capacitors (e-caps) for their DC bus, where large capacitance is required. However, the limited life of e-caps has limited the life of the energy-saving equipment.

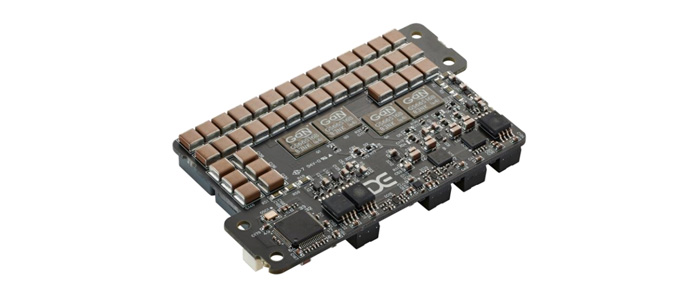

In response, Diamond Electric has developed an “electrolytic capacitor-less (e-caps-less)” technology by fully utilizing its unique controlling algorithm. The technology greatly reduces the capacitance needed in the DC bus by approximately 93%. This allows the use of ceramic or film capacitors instead of e-caps. By adopting ceramic capacitors, Diamond Electric has realized the inverter with prolonged life, lower profile, and higher operating temperature. The e-caps-less assembly is 15% smaller in the volume than the e-caps in DC bus at the same performance NOTE.

In the technology, Diamond Electric has adopted active power decoupling (APD) method. Conventional APDs requires the modification in inverter, PFC, or system control. In contrast, Diamond Electric’s unique controlling algorithm enabled the plug-and-play. Thus, e-caps-less is feasible without modifying inverter, PFC, or system control.

Furthermore, the use of gallium nitride (GaN) power semiconductor enabled the achievement of low losses (approximately 5 W) and contribution to the systems’ efficiency.

NOTE: Compared at the condition where inverter output power is 1 kVA and power factor is 0.99.

Expected Applications

EVs:

- Onboard chargers

- Onboard AC power supply

Energy Saving Equipment:

- Battery energy storage systems for household use

- Solar inverters

- Uninterrupted power supply (UPS) system

- Inverter air conditioners

- Power supply for LEDs

- General purpose power supply

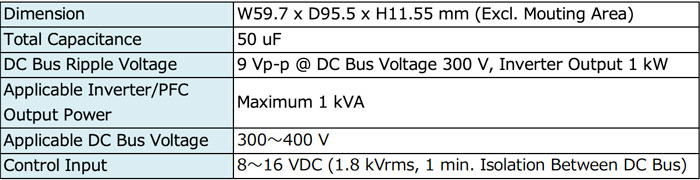

Product specifications:

About Diamond Electric Mfg. Co., Ltd.

As the core member of Diamond Electric Holdings (listed on the Tokyo Stock Exchange (6699), the company is a leading manufacturer of ignition coils for automobiles, operating for 80 years. It also designs and manufactures a variety of DCDC converters, such as solar inverters, onboard chargers and onboard DC/DC converters.

For more details, please refer to https://www.diaelec.co.jp/

Contact

Akihiro Ikenaga

Section to the President

TEL: +81-6-6302-8141

E-mail: PR1_INFO@po.diaelec.co.jp